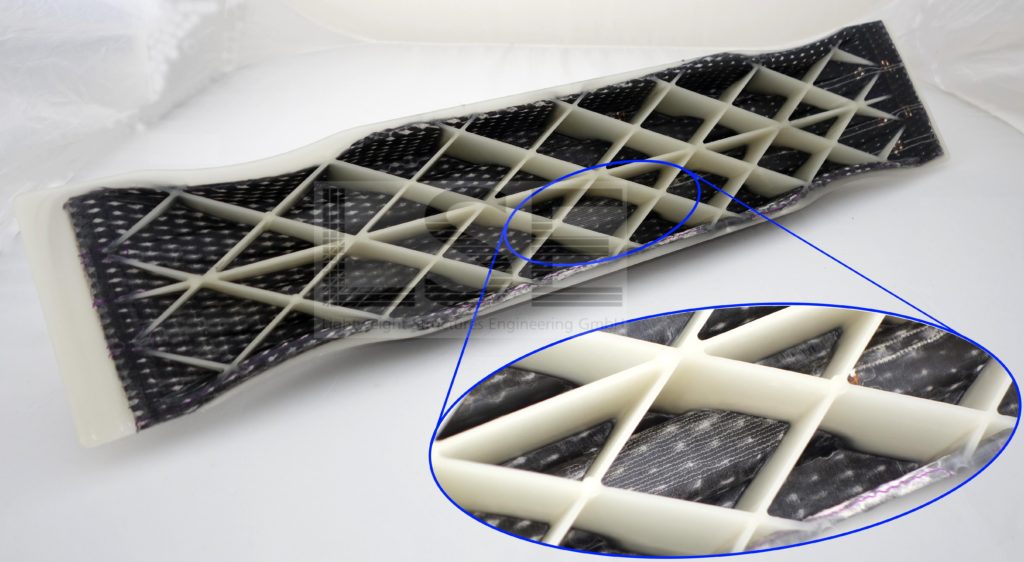

We offer individually adapted sensor and actuator systems which are mainly suitable for an integration into fiber composite structures on the basis of textile semi-finished products. These textile sensors on technical textiles are produced using the tailored fiber placement method (TFP). The preferred sensor materials are wire-based. Depending on the respective application, these systems can be configured for strain, temperature, contact, moisture or fill level.

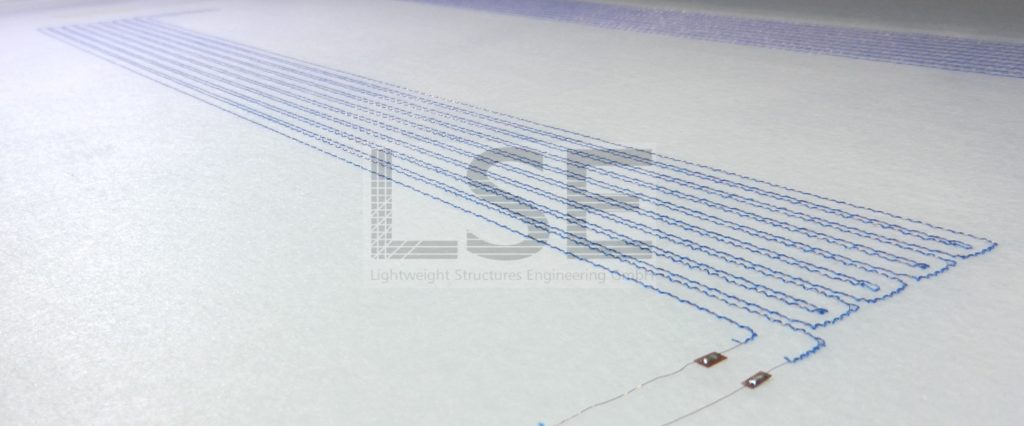

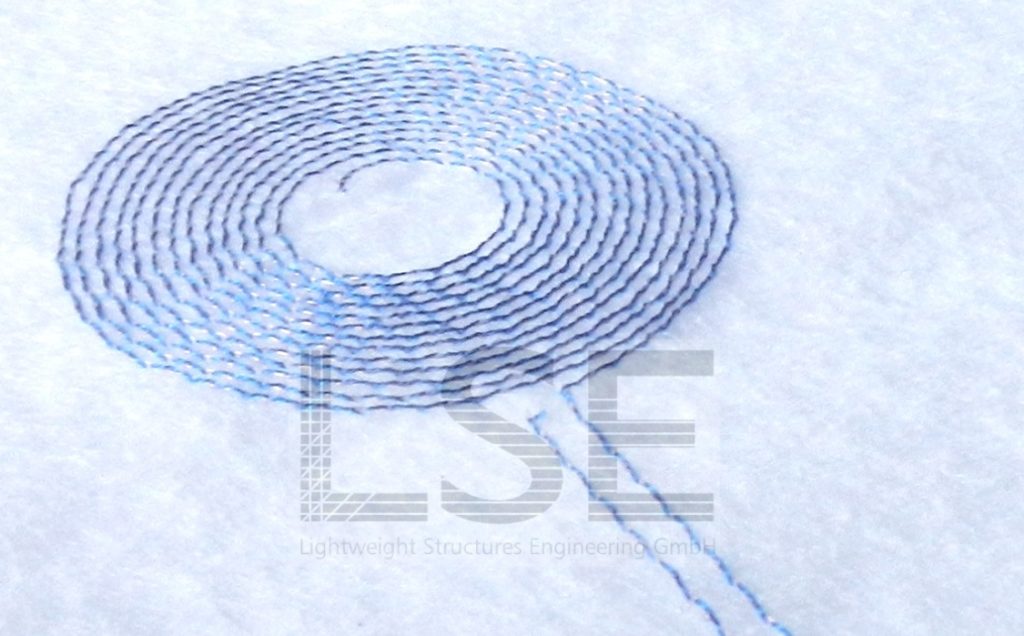

Stitched strain gauges

Stitched strain sensors are used for structural health monitoring by measuring strain in fiber composite components. They can be easily integrated into fiber composites.

Their advantages in comparison to conventional sheet-based strain gauges are:

- Excellent connection to the plastic matrix due to the textile carrier material

- Exact CAD supported positioning of the sensor on the textile semi-finished product

- Individual sensor layouts are also possible for small series or single-unit production

Sensor types:

- standard type 120: strain gauge 120 Ω

- standard type 350: strain gauge 350 Ω

- standard type 500: strain gauge 500 Ω

- standard type 1000: strain gauge 1000 Ω

- Further values and layouts according to customer request possible: info@lse-chemnitz.de

References:

(For additional information please click on the respective image)

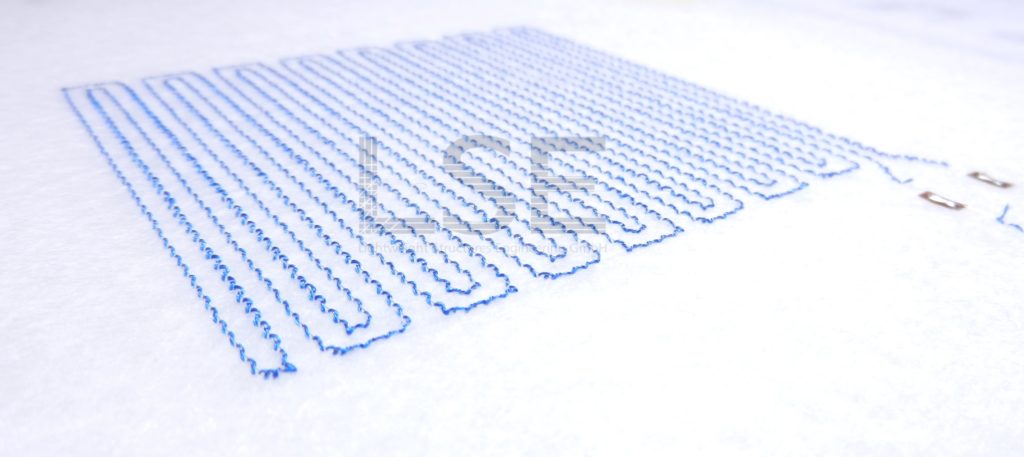

Temperature sensors

Stitched temperature sensors are used to measure temperature and temperature changes in fiber composite components (FKV).

Their advantages over conventional temperature sensors are:

- Measurement of the average temperature of the whole area is possible with one sensor only

- Exact CAD supported positioning of the sensor on the textile semi-finished product

- Individual sensor layouts are also possible for small series or single-unit production

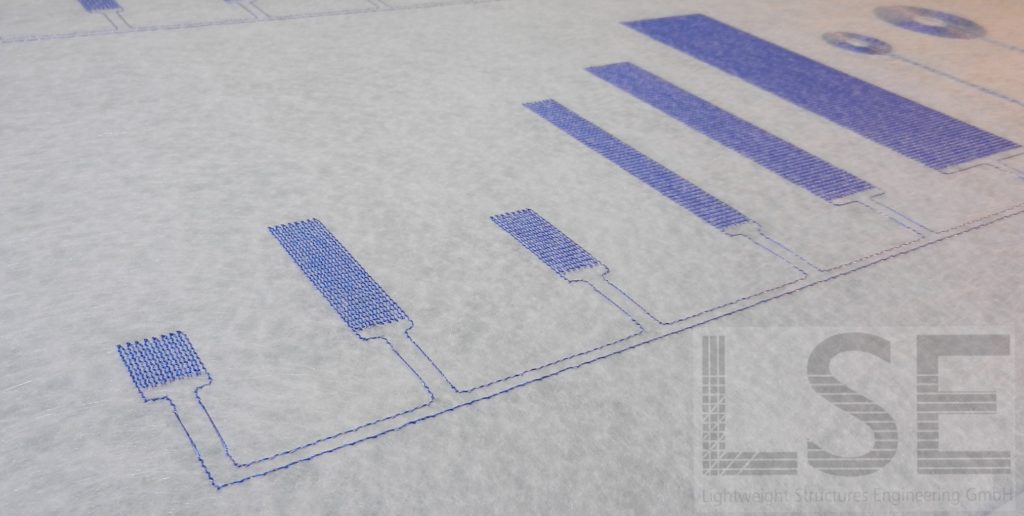

Touch sensors

Stitched touch sensors allow for the integration of switch and touch functions in fiber composite components and are therefore used for the functionalization and realization of smart materials.

Their advantages over conventional switching elements are:

- Integration into surfaces (protected against moisture and dirt, designed shape of the components remains unchanged)

- Exact CAD supported positioning of the sensor on the textile semi-finished product

- Individual sensor layouts are also possible for small series or single-unit production

Fill level sensors

Stitched fill level sensors are used to detect filling levels in fiber composite containers.

Their advantages over most conventional fill level sensors are:

- No contact with the measuring medium due to their integration into the container wall

- Application in container walls of any shape or form

- Individual sensor layouts are also possible for small series or single-unit production